INTRODUCTION

Agriculture is the supporting structure of the Indian economy; however, the growth in the agriculture sector has been slow. The government of India, through the National Bank for Agriculture and Rural Development (NABARD), has initiated several welfare measures – increasing agricultural credit, technology transfer, strengthening agricultural extension, supporting and popularizing new and appropriate technologies, improving market access and linkages - to accelerate the growth in this sector.

|

Preparation of biopesticide - Amirthakaraisal is in progress |

The Farmers' Technology Transfer Fund (FTTF) of NABARD is one such initiative that aims to disseminate appropriate technologies among farmers that could improve their livelihoods. The Centre for Indian Knowledge Systems (CIKS), with support from the FTTF has initiated the “Creating Livelihoods through Organic Farming” - a program that has been supporting farmers in the switch to more sustainable methods of food production and empowering them to take responsibility to enhance their livelihood opportunities.

The implementation of this project started from 01 September 2010 with the involvement of 40 farmers from 3 villages – Adhamangalam (15 farmers), Ilayamadhukoodam (9 farmers) and Pagasalai (16 farmers) covering a total area of 41.62 acres. These beneficiaries received intensive training on various aspects of organic agriculture as well as financial assistance and technical support to set up rural agri-business enterprises. One such initiative is the bio-pesticide production unit in the Adhamangalam village.

THE BIO-PESTICIDE PRODUCTION UNIT IN ADHAMANGALAM

The Adhamangalam village in the Sirkazhi block was selected as one of the beneficiary villages of this FTTF supported program. The village has about 16 (SHGs). The Ponni Iyarkai Vyavasaya Mahalir Kuzhu is one such group that has been actively participating in the various organic agriculture programs conducted by CIKS. During discussions with farmers, it was clear that availability of organic inputs for soil fertility management and pest and disease control was one of the serious limiting factors in the adoption of organic practices.

The idea of setting up small scale production facilities for organic inputs within the village came up during farmers' club and SHG group meetings. The trainings and orientation programs conducted by CIKS instilled a sense of confidence in the women of the Ponni SHG to venture into commercial production of organic inputs for organic agriculture. They have a commercial vermicompost production unit and a bio-pesticide manufacturing unit in the village. CIKS has been assisting them in this endeavor, of creating off-farm income generation activities. The following five women from the Ponni SHG – Mrs. Sudha, Mrs. Jhanci Rani, Mrs. Valarmathi, Mrs. Damayanti and Mrs. Kaliammal - were identified and selected to set up this bio-pesticide unit. The responsibility of ensuring timely production of good quality plant protection inputs has been handed over to these five women.

|

Beneficiaries preparing Panchakavyam - a plant growth promoter |

They are well trained and experienced in the preparation of the following plant protection inputs.

• Panchagavyam

• Neem Seed Kernel Extract

• Neem cake extract

• Five leaf Extract

• Ginger/Garlic/Chilli extract

• Vasambu extract

Since the shelf life of most of the organic plant protection inputs is very limited (a maximum of 1-2 days) they are produced only when there is a demand or order. The only exception to this is panchagavyam which has a shelf life of about 4-6 months. This alone is prepared in advance since its preparation includes a 21 day fermentation period. Once prepared it is stored under appropriate conditions so that its potency is not lost or reduced.

When venturing into a commercial mode of production it is essential to have a common production facility where the women can come and work. Since the women stay scattered in different places in the village, a common and conveniently located site, easily accessible to all the five women and one that had access to water was identified within the village to set up the input production unit. A small shed measuring 10' x 10' has been constructed to prepare and store the inputs. The basic tools and implements required for the manufacture of inputs have also been purchased for the Ponni SHG. They have five barrels in which the extracts are prepared and stored, a sieve to filter the extracts, two sprayers that they use for spraying the extracts in their demonstration kitchen garden unit. As publicity material they also have five banners stating the products they manufacture and their contact details. The unit is bolted and locked with a chain to ensure that there is no loss or theft of materials.

|

Preparation of ginger, garlic, chilli extract |

The cost of infrastructure (in rupees) works out as follows:

• Cost of shed – 10,000.00

• Plastic barrels (5 nos.) – 1,000.00

• Sprayers (2 nos.) – 3300.00

• Locks, filters chains – 410.00

• Publicity material (5 banners) – 1,000.00

• TOTAL COST – 15,710.00

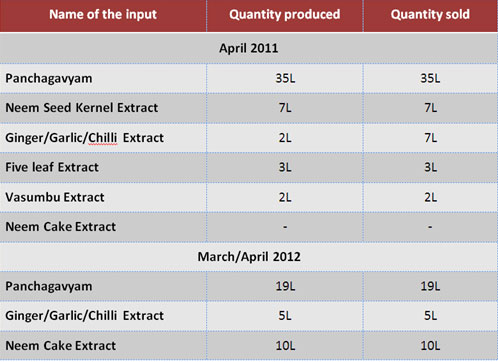

Table 1 shows the quantity of inputs produced and sold from the Adhamangalam Input Production Facility since the start of the project in September 2010

TABLE 1: Production and Sales of Inputs produced by the Adamangalam Ponni SHG

MARKETING EFFORTS

It is interesting to note that local sales have been less when compared to sales to other villages. The Ponni SHG has supplied inputs to Chidambaram, Bhuvanagiri, Kollidam, Achalapuram, Ilayamadhukoodum, Pagasalai, Nallavinayagapuram and Kuthianpettai. One of the possible reasons for this could be that, a number of training programs have been conducted in Adhamangalam and other villages that are beneficiary villages of the organic agriculture program of CIKS, that farmers themselves have the knowledge of preparation of plant extracts.

The inputs have been sold at the following prices so far, but since production costs have increased, they are looking to revise the selling price shortly.

• Panchagavyam – Rs. 50/L

• Neem Seed Kernel extract – Rs. 30/L

• Ginger/Garlic/Chilli extract – Rs. 30/L

• Neem Cake extract – Rs. 25/L

• Five leaf extract – Rs. 25/L

• Vasambu extract – Rs. 60/L

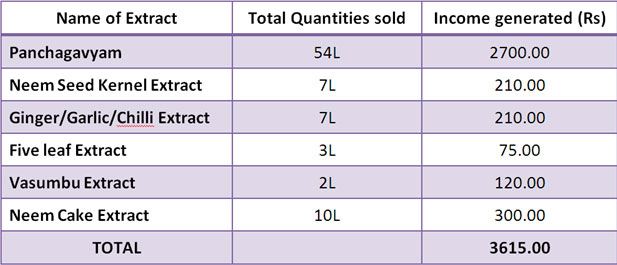

TABLE 2 – Income generated from sales of organic inputs

This is the initial year of production and the women are slowly learning the nuances of production, advertising and marketing. They are hopeful of increasing sales in the coming season, since they are actively advertising their products in rural exhibitions, and training programs. In fact these women have become so confident that they are able to provide trainings to other farmers in this area. This could become another source of income for the group.

PRODUCTION OF VALUE ADDED PRODUCTS AT PAGASALAI

Under the “Creating Livelihoods through Organic Farming” program, the TANWABE women's group of Pagasalai village (one of the beneficiary villages of the organic agriculture program of CIKS) has started a production facility for value added rice products. Four women of this TANWABE group have come together to set up the production facility. The TANWABE group is nurtured and supported by the Karikalan Farmers Club at Pagasalai. The members of this farmers club have been following organic management practices for paddy, black gram and green gram for the last few years. As part of their organic agriculture program and biodiversity conservation program they have been growing a number of traditional paddy varieties. Some of these traditional varieties are suitable for preparation of rice papads and vadagams.

The women of this group identified a potential for income generation and with the support and mentoring of CIKS have set up a production facility for rice papads, vadagams and other value added products like puttu powder and rice flour in the village. In December 2010 these four women came together to form a Joint Liability Group (JLG) to be able to access credit facility from banks to set up their business enterprise. CIKS has also given them a loan of Rs.25,000/- to build the business enterprise.

|

Grinding flour for the preparation of value added product |

The enterprise has been set up in a room in the village that has been lent by one of the members of the TANWABE group. In the initial phase, the grinding work was done manually and the steaming of the papads was done on leaves using firewood. This was getting a little cumbersome and labor intensive and production capacity was low. It was enough when the demand for the product was small, but with increasing demand for the products, the women realized the need for improving efficiency of production. This was possible only if the process could be mechanized to a certain degree. The following infrastructure has been added to the enterprise now.

|

Preparation of value added product - Vadam |

• Electricity connection

• Drier

• Gas connection and gas stove

• Domestic flour mill

• Pulverizer

• Stainless steel utensils

• Weighing machine

• Sealing machine

• Labels

CIKS has provided the funds as a grant to the TANWABE group for the purchase of the Drier, Pulverizer, stainless steel utensils and Domestic flour mill.

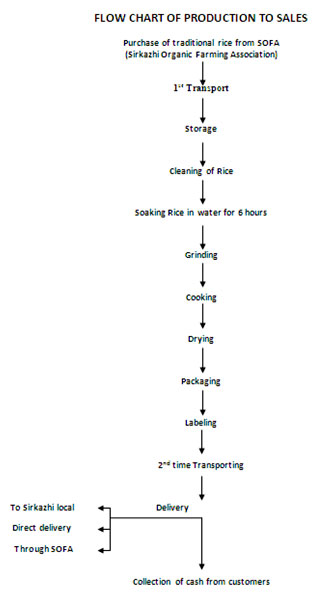

The production process starts with the purchase of traditional varieties from the Sirkazhi Organic Farmers Association (SOFA) and ends with the final sales of the product. The women have been involved in the entire range of activities starting from production to marketing of their produce. The flow chart explains in detail the various stages of production till final marketing of produce.

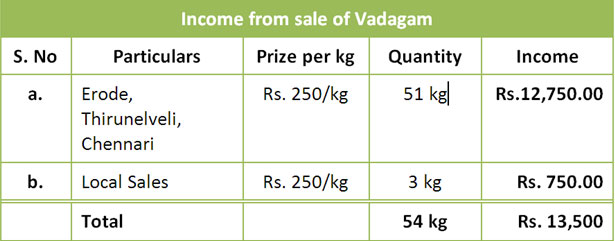

The products are being sold under the brand name ‘Pavai' and the market for the produce has been steadily increasing ever since they started production. A noteworthy feature is that the women are actively involved in all stages of production and marketing. They have been participating in a number of food expos and exhibitions and the response that they have been receiving has been very encouraging. Their products are now being sold in Sirkazhi, Chidambaram, Coimbatore, Salem, Erode, Tirunelveli and Chennai. They are participating in exhibitions and other public functions and promoting their products to a wider customer base. The production and sales details are given in Table 3 and Table 4.

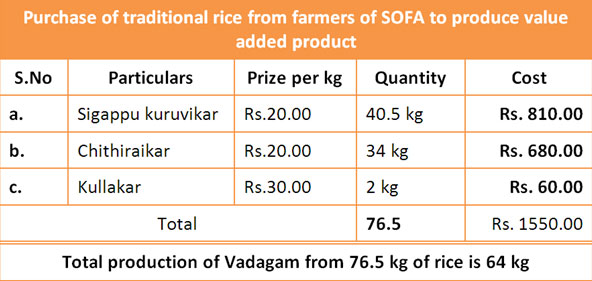

TABLE 3 – Purchase details of value added rice products by TANWABE group

TABLE 4 – Sales details of value added rice products by TANWABE group

The group has incurred other costs including repayment of loans, buying of other ingredients, transportation charges, packaging charges, electricity charges, marketing expenses and depreciation charges. It has been calculated that the group makes a profit of Rs. 66.12/- per kilogram of products sold.

These women have been sufficiently trained in all aspects of production and marketing that they are now confidently conducting training programs for women's' groups from other parts of Tamil Nadu. W omen SHG members from Swayam Shikshak Prayog (SSP), Cuddalore district have visited this group and based on the experience gained during their visit have already started production in Cuddalore District. Mrs.Jayalakshmi, Organiser of the TANWABE group visited these two villages - Agathariruppu and Pottakulam in the Kamudhi taluk of Ramnathapuram district on December 10 and 11, 2011 to train 40 women from four SHG's in the preparation of rice papads and vadagams. This newly trained group has also started production of these products.

Conclusion

As an initial effort at managing a rural business enterprise the efforts of both these women's groups need to be appreciated and supported. The women managing this input production facility are ones who have not, prior to the organic agriculture program of CIKS, ever stepped out of the confines of their homes. They have broken the social barriers imposed by society on women and have taken the first step towards economic independence and self reliance. They have created livelihood opportunities for themselves and are now contributing to family income. Most important is the fact that women are empowering themselves and supporting the development of their village. Doubtlessly the efforts of these women need to be acknowledged and supported.

BACK TO TOP^

|